www.wimb.net - Numerical Control History

Sequential Facets of N/C

Reading Blueprints

Writing Programs

Preparing the Tape

Verifying the tape

Mounting the Tape in the Console Reader

Making Machine Tool Adjustments

Testing Machine Tool Performance

Producing Parts through Automatic Repeat Performances

Storing Tapes for Future Production Uses

Research and Development Contributions to N/C

Tape Fabrication

Tape Perforating Equipment

Performance Commands and Number Language

Program Writing

Code-on-tape Number Formats

Sequential Facets of N/C

Preparation for numerical control begins already during the design stage. The part must be designed and drawings dimensioned for ease of production on N/C equipment. Beginning with a finished blueprint, a numerical control program are shown in the illustration on the right.

"R and D" Contributions to N/C

Refinements for N/C represent considerable research and development during the last two decades. Contributions toward the improvement of programming language, techniques, and materials are many and also diverse. The following model identifies the areas of numerical control in which "R and D" personnel have worked diligently. Their refinements of these innovations have led to standards which have been commonly accepted in the N/C world of work.

The category, 'Tape Materials", refers to the selection and subsequent development of materials used in manufacturing this kind of input media. "R and D" efforts and activities were indeed centered and well-founded in the field of chemistry. Certainly a variety of chemicals have been used in the research activities toward the making of desirable paper tape combinations, plastic tape combinations, and other special refinements in tape materials. "R and D" contributions have brought about tapes which have the properties of uniform width, uniform strength and increased resistance to wear, tear, and oil.

"Tape Fabrication" refers to the standards by which an input tape is fabricated or manufactured. Manufacturers have been concerned with the uniformity in chemical composition of the basic tape material or combination of materials, the uniformity of the physical properties such as strength, thickness, width, resistance to static electricity, and finally the preparation of devices in which the finished tape may be stored and shipped with a minimum of possibilities for tape damage.

Perforating Tape

Pieces of equipment used for perforating the tape have seen many changes. Electronically operated perforating equipment is now available from a number of manufacturers. A skillful operator of some of the refined perforators may be extremely productive in preparing tapes for the control panel. One common electronically operated standardized through the efforts of Electronics Industries Association and is known as the EIA Standard. The other format commonly used is known as the American Standard Code for Information Interchange and is abbreviated as ASCII The SLO-SYN N/C System is adaptable to both formats, the EIA and the ASCII. The reader should note that the designs of the formats have many similarities.

Pieces of equipment used for perforating the tape have seen many changes. Electronically operated perforating equipment is now available from a number of manufacturers. A skillful operator of some of the refined perforators may be extremely productive in preparing tapes for the control panel. One common electronically operated standardized through the efforts of Electronics Industries Association and is known as the EIA Standard. The other format commonly used is known as the American Standard Code for Information Interchange and is abbreviated as ASCII The SLO-SYN N/C System is adaptable to both formats, the EIA and the ASCII. The reader should note that the designs of the formats have many similarities.

Some common performance commands have been established as programming standards. Number codes-on-tape assigned to the different performance commands have also been standardized. Specific performance commands with appropriate explanatory information of each will be presented in a later chapter.

Primary contributions in program writing have been centered on the subject of communications. In the interest of efficiency, communication between the product engineer, the draftsman, the programmer, and the machine operator has had to be improved. The commands, the language to describe the commands, and the procedure for recording the language on the programming sheet have been refined and since standardized. Refining and standardizing the programming sheet has facilitated consistent programming practices.

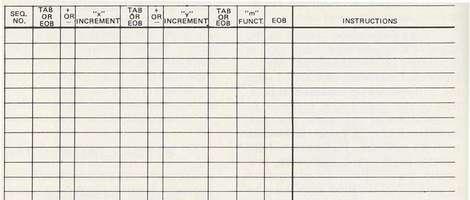

Programming Worksheet

Below is a sample of a programming format used by the programmers of the SLO-SYN N/C System.

Tape Standards

Finally there are two well known code-on-tape formats which have been developed through the years and are now standardized. Both formats employ a binary number concept. The function of the code-on-tape format is to establish, for communications purposes, the prescribed perforation design of each symbol or numeral to be recorded on N/C tape.

The machine Operator

The role of a machine operator for numerically controlled machine tool operations has changed significantly, but he is still very much a part of the total N/C process. Essentially, his role has changed from operating and controlling machine tools manually to:

- maintaining high-level performance of automatically controlled machine tools

- feeding back information to the programmer for the purpose of improving programmed instructions

In the interest of safety and efficiency, the new role of the operator is such that a reduction in length of training is possible for the development of necessary skills. The model depicts the primary functions of the machine tool operator.

Updated 2007 Oct. 09