www.wimb.net - Solder Flux Spray Station

Used materials

Control SS2000D3i

Stepper Motor KML091F07

Solder Flux Spray Station

This company has a very old soldering machine for printed circuit boards. The machine was good working, except the section were the flux was put on the printed circuit boards. They decided to remove the old flux section and to replace it by a new, special designed stepper motor driven flux station.

The solution is made with a SS2000D3i programmable stepper motor control, a KML091F07 high torque motor and a 350 mm slide from Tollo. The SS2000D3i controls the motor position and speed, the open and closing of the spray nozzle and the on/off of the flux liquid pump.

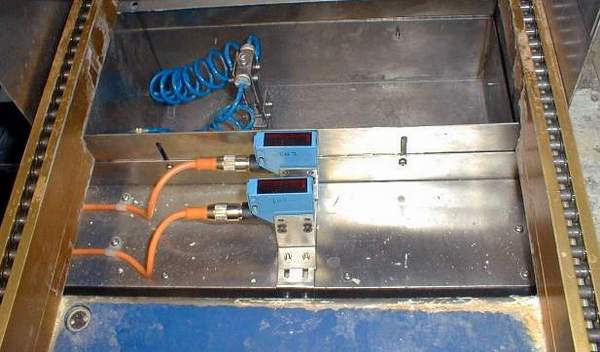

Since all printed circuit boards are longer then the distance between the two sensors, the program waits till both sensors are activated. Then there is a delay to cover the distance between the sensors and the spray nozzle. The pump is switched on, and then nozzle starts moving and spraying.

During this the program watches the sensors. When they are inactive, then some extra flux cycles are made to go up till the end of the printed circuit board. If within 3 seconds the sensors are closed again then the control continues with the flux cycle. If the sensors are still open then the control thinks that this was the end of fluxing several boards. It switches of the flux pump and goes back to the start position, waiting for new boards.

A view on the solder machine at the side where the printed circuits boards enters the machine. The flux station is just at the beginning.

The two sensors and the spray nozzle. At the left and right there is the chain transport system for the printed circuit board holders.

Updated 2007 Oct. 09